Reliable Supplier of Various Glass Insulator Sizes

Product Main Parameters

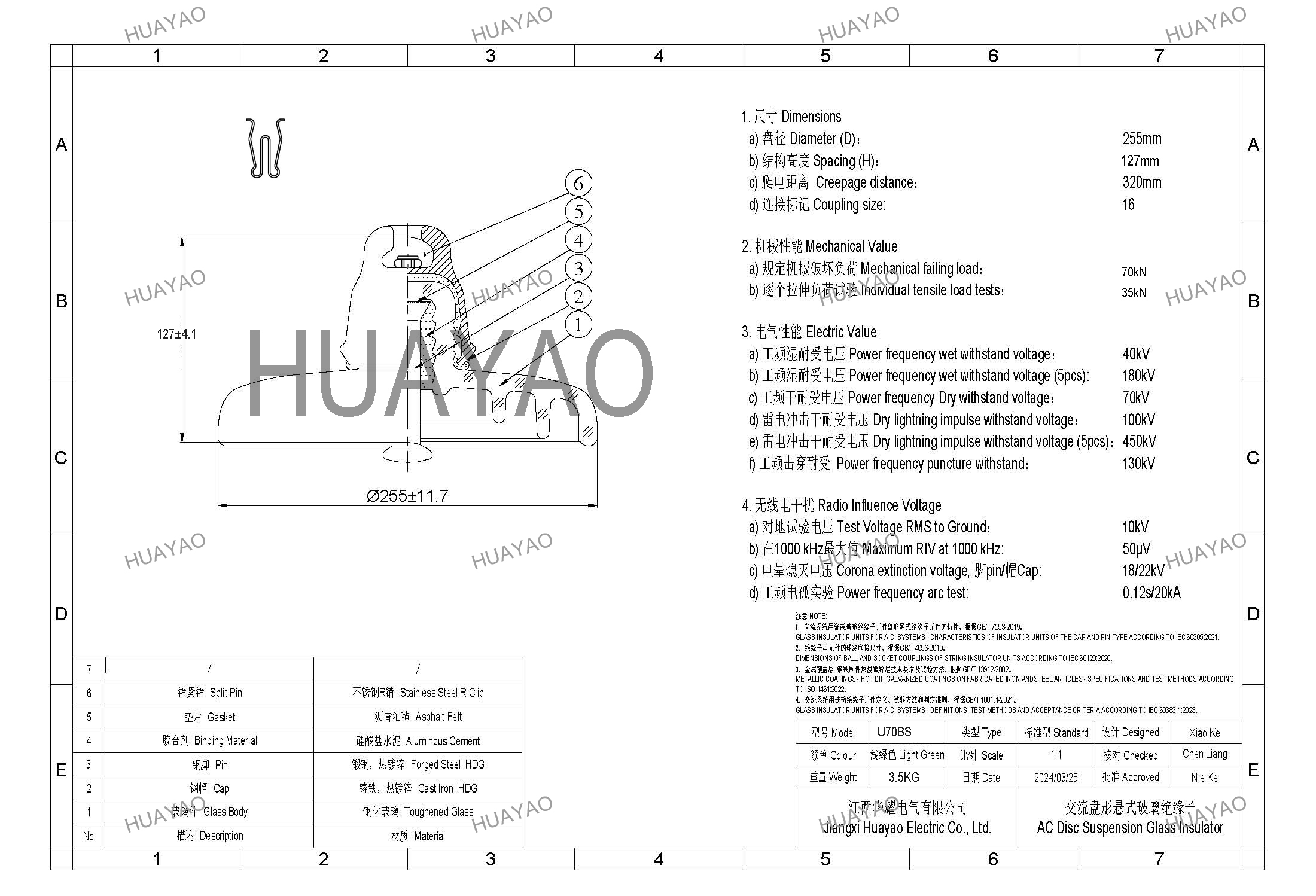

| Model | Diameter (D) | Spacing (H) | Creepage Distance (L) | Mechanical Load (kN) |

|---|---|---|---|---|

| U70BS | 255 mm | 127 mm | 320 mm | 70 kN |

Common Product Specifications

| Attribute | Value |

|---|---|

| Rated Voltage | 33 kV |

| Material | Fiberglass |

| Color | Jade Green |

| Origin | Jiangxi, China |

Product Manufacturing Process

The manufacturing of glass insulators involves several critical stages to ensure quality and reliability. Initially, raw materials are carefully selected and screened. The process starts with the melting of high-quality glass in natural gas kilns. After melting, the glass is molded into the desired shape using advanced pressing techniques. The insulators then undergo a uniform tempering process, which enhances mechanical strength and thermal shock resistance. Next, they are subjected to cold and hot impact treatments to ensure durability under varying environmental conditions. The final steps include homogenization treatment for consistent quality, followed by inspection and packaging. Adopting state-of-the-art technology ensures that each insulator meets global standards for safety and performance.

Product Application Scenarios

Glass insulators are pivotal in electrical transmission and distribution systems, providing essential insulation between electrical conductors. They are widely utilized in overhead transmission lines, substations, and transformer stations. These insulators are particularly crucial in high-voltage applications where reliability and safety are paramount. In polluted and salty environments, specially coated or larger-sized insulators are recommended to maintain performance levels. By serving these critical roles, glass insulators help in minimizing energy losses and preventing electrical failures, ensuring a stable power supply across various landscapes from urban to rural settings.

Product After-Sales Service

Our commitment to customer satisfaction is reflected in our comprehensive after-sales service. We provide full support for installation and maintenance, ensuring the optimal performance of our glass insulators. Our technical team is available for assistance throughout the product lifecycle. Additionally, customers can benefit from warranty services and can reach out for repairs or replacements as needed.

Product Transportation

Efficiency and safety are our priorities in product transportation. Our glass insulators are packed in wooden cases and secured on pallets for stable and damage-free transit. We collaborate with reliable logistics partners to ensure timely delivery to your location, whether it's domestic or international shipping.

Product Advantages

- High Quality: Manufactured using advanced technology to meet international standards.

- Durability: Designed to withstand harsh environmental conditions.

- Versatility: Available in various sizes to suit different voltage levels and applications.

Product FAQ

- What are the main components of a glass insulator?

Glass insulators consist of tempered glass pieces bonded with iron caps and steel feet using cement adhesive. This construction ensures mechanical strength and electrical insulation. - Why are glass insulators used in power transmission?

Glass insulators are utilized for their excellent insulating properties, mechanical strength, and durability. They prevent electrical discharge and maintain safety across transmission lines. - Are there different sizes available for glass insulators?

Yes, our company provides various glass insulator sizes to address different voltage requirements and application needs, ensuring compatibility with diverse electrical systems. - Can glass insulators handle extreme weather conditions?

Our glass insulators are designed to perform efficiently in various environmental conditions, including high pollution, humidity, and salty areas, ensuring reliability and stability. - How is the quality of glass insulators ensured?

The quality is maintained through stringent screening of raw materials, adherence to manufacturing standards, and thorough testing throughout the production process. - What certifications do your glass insulators possess?

Our insulators are certified under ISO9001 for quality management and comply with IEC 60383 standards, ensuring global acceptance and reliability. - How are glass insulators packaged for shipping?

They are carefully packed in wooden cases and placed on pallets toprevent damage during transit, ensuring they reach you in perfect condition. - What maintenance is required for glass insulators?

While glass insulators are low-maintenance, regular inspections are recommended to identify any signs of wear or damage, ensuring continued performance and safety. - Why choose us as your glass insulator supplier?

We are a direct factory with advanced manufacturing equipment, offering you high-quality products at competitive prices while ensuring exceptional service and support. - What is the delivery time for orders?

Delivery time varies based on order size and location, but we strive to ensure timely distribution through our efficient logistics network. Exact timelines can be discussed upon order placement.

Product Hot Topics

- The Importance of Insulator Size in Power Transmission:

Insulator size plays a crucial role in the efficiency of power transmission. Larger insulators provide more reliable insulation and are better suited for high voltage applications. Choosing the correct size ensures minimal energy loss and maximizes safety. - How Suppliers Influence Quality in Electrical Components:

A reliable supplier ensures that all components meet strict quality standards and perform well in real-world conditions. Partnering with the right supplier can lead to improved system reliability and longevity. - The Evolution of Glass Insulator Manufacturing:

Advancements in technology have greatly enhanced the production of glass insulators, resulting in products that offer better performance and durability. Modern manufacturing methods focus on quality control and environmental sustainability. - Environmental Considerations in Insulator Design:

Designing insulators involves considerations for various environmental factors, such as pollution, humidity, and temperature changes. Understanding these factors helps in developing insulators that maintain performance under all conditions. - Global Standards and Compliance in Glass Insulator Production:

Working with a supplier that adheres to global standards is essential for ensuring product quality and compatibility. Standards like IEC 60383 provide guidelines for performance, safety, and reliability. - The Role of Insulators in Modern Power Grids:

As power grids become more complex, the role of insulators in maintaining system stability becomes increasingly critical. They support the safe and efficient distribution of power across vast networks. - Supplier Relationships and Their Impact on Project Success:

Choosing the right supplier can significantly impact the success of power projects. A trusted supplier ensures timely delivery and quality products, contributing to overall project efficiency. - Technological Innovations in Insulator Materials:

New materials and coatings are being developed to enhance insulator performance, particularly in adverse environmental conditions. These innovations aim to extend the lifespan and reliability of insulators. - Challenges in the Insulator Industry:

The industry faces challenges such as raw material costs and environmental impact. Addressing these challenges requires innovation and sustainable practices to maintain a competitive edge. - Future Trends in Glass Insulator Applications:

As renewable energy sources become more prevalent, the demand for efficient and reliable insulators grows. Future trends focus on enhancing insulator capabilities to support evolving power systems.

Image Description

Phone

Phone

whatsapp

whatsapp

Email

Email