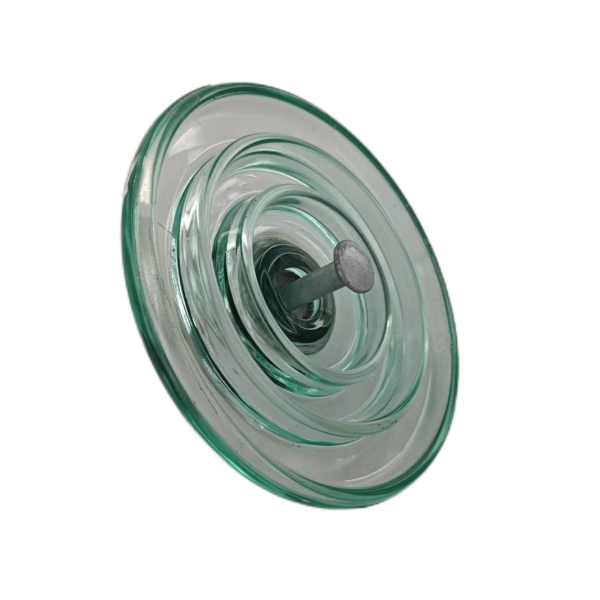

High Voltage Glass Insulators Manufacturer | 5 Electrical Insulators

Product Main Parameters

| Model | Diameter D (mm) | Spacing H (mm) | Creepage Distance L (mm) | Mechanical Failing Load (kN) |

|---|---|---|---|---|

| U160BL/170 | 280 | 170 | 400 | 160 |

Common Product Specifications

| Material | Application | Rated Voltage | Brand | Origin |

|---|---|---|---|---|

| Fiberglass | High Voltage | 33kV | Huayao | Jiangxi, China |

Product Manufacturing Process

Our advanced manufacturing process incorporates cutting-edge technology, beginning with the selection of premium raw materials. The integration of automatic batching systems ensures precision in component measurement, minimizing potential errors in the subsequent stages. High-temperature melting is followed by precise pressing and tempering, which grant the glass insulator its significant mechanical strength. The process concludes with thorough inspections, ensuring that each unit adheres to industry standards before packaging and shipment. This meticulous approach results in superior glass insulators that meet the rigorous demands of high-voltage applications.

Product Application Scenarios

High voltage glass insulators are crucial in power transmission, ensuring the stability and safety of electrical networks. They are widely used in overhead transmission lines, offering insulation and mechanical support for conductors. These insulators withstand environmental factors such as rain, pollution, and temperature fluctuations, making them ideal for diverse climates. Additionally, their resistance to thermal and mechanical stresses confirms their reliability in international power grid infrastructures. The strategic deployment of these insulators contributes to uninterrupted power supply and enhances the efficiency of energy distribution systems.

Product After-Sales Service

Our commitment to exceptional customer service includes comprehensive after-sales support. We provide technical assistance, product maintenance guidance, and a warranty to ensure customer satisfaction. In the event of a defect, our team swiftly addresses issues to minimize downtime, reinforcing our dedication to quality and reliability.

Product Transportation

Our logistics team ensures the safe and efficient transportation of glass insulators, utilizing sturdy packaging materials to protect against potential transit damage. We coordinate with reputable carriers and offer tracking services to ensure timely delivery to our customers worldwide.

Product Advantages

Our glass insulators offer standout advantages such as high mechanical strength, excellent electrical insulation, and resistance to environmental impacts. Enhanced durability and competitive pricing make them a preferred choice for global power systems.

Product FAQ

- What materials are used in manufacturing? We utilize fiberglass for mechanical strength and advanced tempered glass for optimal insulation, ensuring high performance.

- How do you ensure product quality? Our manufacturing employs stringent quality controls, from raw material selection through to final inspections, adhering to international standards.

- What applications are these insulators best suited for? Our insulators are ideal for high voltage power transmission lines, offering superior performance in varied climatic conditions.

- Are the products tested before shipment? Yes, every insulator undergoes rigorous testing to verify compliance with GB, ANSI, BS, and DIN standards, among others.

- Do you offer custom solutions? As a manufacturer, we provide customized designs to meet specific customer requirements in diverse applications.

- What is the lifespan of your insulators? With proper installation and maintenance, our glass insulators offer a lifespan exceeding 30 years, even in challenging environments.

- How do you handle large orders? Our production capacity exceeds 6 million units annually, enabling us to efficiently fulfill large orders while maintaining quality.

- What certifications do your products have? Our insulators are certified under ISO9001 and meet stringent international standards for quality assurance.

- What is the delivery time for orders? Delivery time typically ranges from 2 to 4 weeks, depending on the order size and destination.

- Do you offer installation support? While we do not offer on-site installation, our customer support team provides comprehensive guidance and resources to assist in the installation process.

Product Hot Topics

- Innovation in Glass Insulator Manufacturing: As a leading manufacturer, our focus on innovation in the production of 5 electrical insulators has resulted in breakthroughs enhancing efficiency and reliability.

- The Role of Glass Insulators in Sustainable Energy Systems: Glass insulators are pivotal in sustainable energy systems, offering solutions that enhance transmission efficiency and reduce environmental impact.

- Challenges and Solutions in High Voltage Transmission: Navigating the challenges of high voltage transmission, our insulators offer proven solutions that ensure stability and safety in power systems.

- Advancements in Electrical Insulation Technology: Our ongoing R&D investment in 5 electrical insulators reflects our commitment to advancing insulation technology for superior performance.

- Global Demand for High-Performance Insulators: The rising global demand for high-performance insulators underscores the importance of manufacturers in delivering reliable energy solutions.

- Environmental Benefits of Using Glass Insulators: Glass insulators provide a sustainable alternative, offering significant environmental benefits in power transmission applications.

- Customizing Insulators for Diverse Applications: Manufacturers are increasingly customizing insulators to meet the diverse demands of different power infrastructure projects.

- Quality Assurance in Insulator Manufacturing: Our quality assurance protocols in manufacturing ensure that each of the 5 electrical insulators meets stringent international standards.

- The Impact of Climate on Insulator Performance: Understanding climatic impacts allows manufacturers to tailor insulator materials and designs for optimal performance.

- Future Trends in Electrical Insulation: Future trends in 5 electrical insulators point towards increased efficiency, enhanced durability, and reduced environmental impact.

Image Description

Phone

Phone

whatsapp

whatsapp

Email

Email